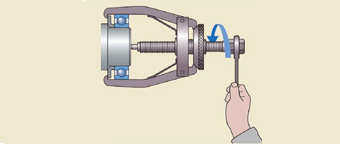

1. Disassembly techniques for NSK bearing races:

Some machinery and equipment are prone to damage to the connecting rod NSK bearing, and after the NSK bearing is damaged, its outer ring is still stored in the connecting rod hole, making disassembly difficult. Due to the fact that all the steel in the outer ring is relatively solid, it is easy to slip when sawing with a hacksaw. However, excessive force can also cause damage to the connecting rod. At this point, the connecting rod can be fixed on the vise. Using a heavy-duty socket wrench insert, use the insert on the side slightly larger than the size of the connecting rod NSK bearing hole to hold the connecting rod hole, and use the insert on the side slightly smaller than the size of the connecting rod NSK bearing hole to hold the NSK bearing outer ring. Then, increase the clamping force appropriately and gradually press the NSK bearing outer ring out.

2. Problems with NSK bearings themselves:

When repairing machinery and equipment, maintenance personnel should have a one-sided understanding of the corresponding NSK bearing code and model information, and avoid using other models of NSK bearings to exchange original NSK bearings. At present, there are significant quality differences among the NSK bearings available in the market, and the occurrence rate of problems such as confusion and substandard products is relatively high. Some NSK bearings may even experience a decrease in quality or function due to prolonged storage time. Therefore, before repairing NSK bearings in machinery and exchanging new NSK bearings, it is necessary to accurately verify the relevant information of NSK bearings, test their functional and surface conditions, and improve the quality of NSK bearings.

3. Do not install NSK bearings upside down:

In the process of machine equipment maintenance, it is necessary to accurately grasp the direction of the NSK bearings of the machine, and only correct installation is needed to provide guarantee for its voluntary operation. Due to the unclear external characteristics of some NSK bearings on certain machines, they can be installed in any direction, resulting in errors during installation. Therefore, when assembling NSK bearings, maintenance personnel need to have a one-sided understanding and accurate grasp of the installation and structural requirements of NSK bearings, as well as a one-sided understanding of the relevant rules in the manual, in order to ensure the accuracy and efficiency of NSK bearing maintenance obligations.

中文

中文 English

English