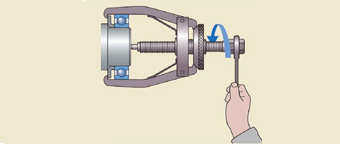

The measurement is carried out using the lead pressing method and the feeler gauge method, and the radial clearance is not indicated in the bearing code. The clearance of the bearing varies according to its inner diameter. According to the table, in general, the radial clearance of the rolling bearing cannot be greater than 0.3% of the inner diameter of the bearing, and the radial clearance of the radial short cylindrical bearing cannot be greater than 0.2% of the inner diameter of the bearing.

The clearance of bearings is also known as bearing clearance.

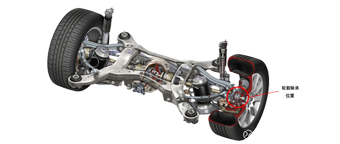

Bearing clearance refers to the amount of movement of a bearing when one side of its inner or outer ring is fixed when it is not installed on the shaft or bearing housing, and then facilitates radial or axial movement of the unfixed side. According to the direction of movement, it can be divided into radial clearance and axial clearance.

Radial clearance: When there is no load, when one ring is fixed, the amount of movement of the other ring relative to the fixed ring in the radial direction from one extreme position to the other extreme position.

Axial clearance: When there is no load, when one ring is fixed, the amount of movement of the other ring relative to the fixed ring along the axial direction from one extreme position to the other extreme position.

To check for bearing damage, it can be found that in most cases, it may cause them. Generally speaking, only one-third of the damage caused by fatigue damage to bearings comes from poor lubrication, and the other one-third comes from pollutants entering the bearings or improper installation and handling. However, these types of injuries are unrelated to the industry. Bearings are precision parts, so it takes a considerable amount of time to use a cautious attitude, even with high-performance bearings. If used improperly, the expected performance effect cannot be achieved, and it is easy to damage the bearings.

Therefore, the use of bearings should pay attention to the following points:

1、 Keeping the bearings and their surrounding environment clean, even the tiny invisible dust that enters the bearings, can increase the wear, vibration, and noise of the bearings.

Secondly, use careful installation to ensure that powerful stamping does not allow direct hitting of the bearing with a hammer, and does not allow pressure to pass through the active network.

Thirdly, use appropriate and accurate installation tools to utilize the use of special tools, avoiding the use of fabrics and short fibers as much as possible.

Fourthly, when preventing bearing corrosion, select the bearing directly by hand, thoroughly wash the sweat from the hands, and then apply high-quality mineral oil to prevent rust. However, under certain special operating conditions, bearings can achieve a longer lifespan than traditional calculations, especially under light load conditions. These special operating conditions are that when the rolling surface (track and rolling parts) is an effective lubricating film to separate and limit pollutants, surface damage can occur.

中文

中文 English

English